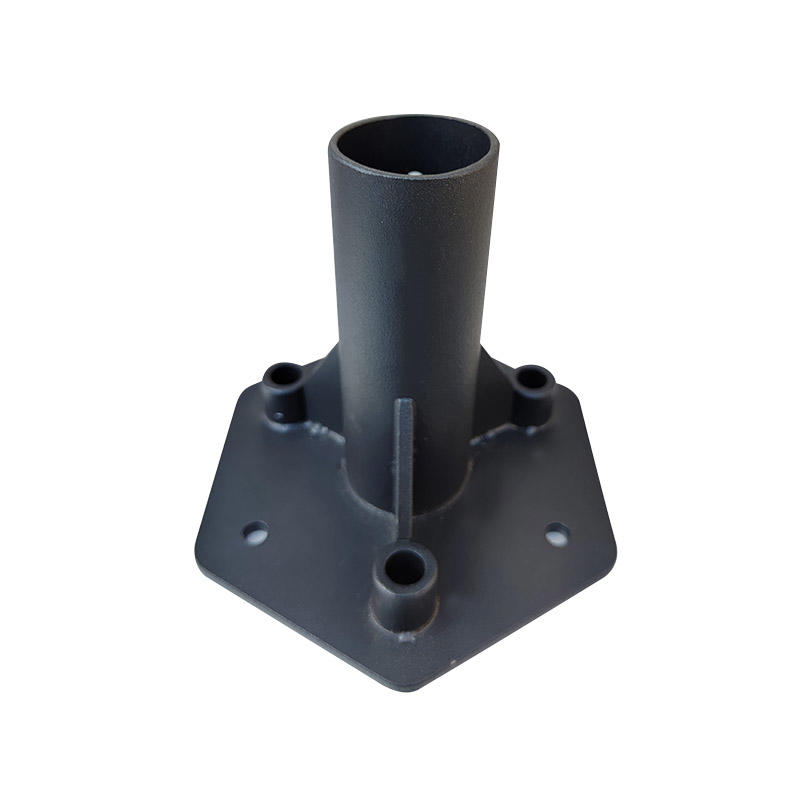

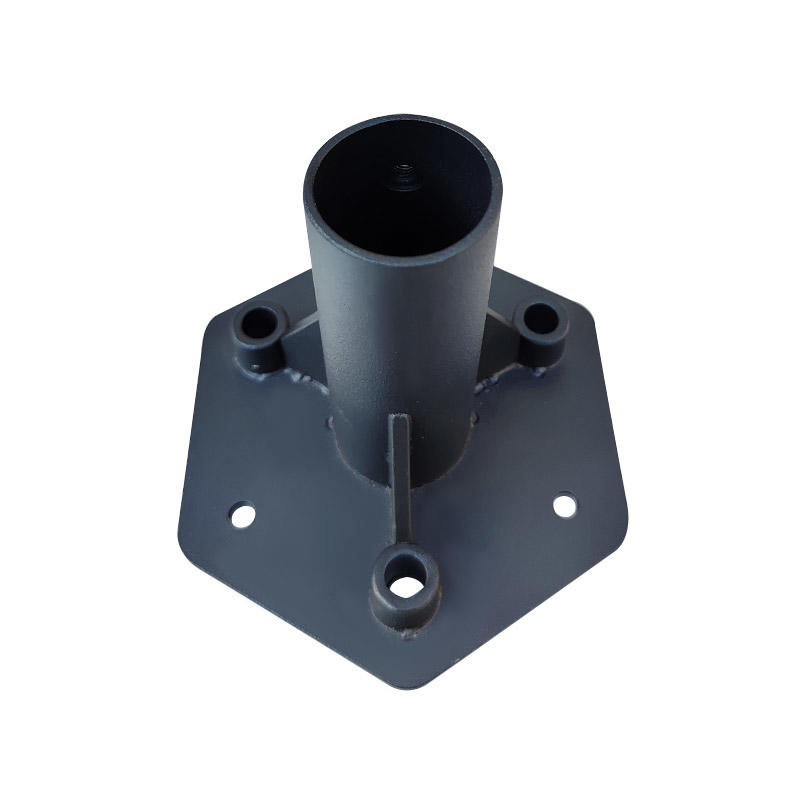

Features And Applications Of High-Precision Sheet Metal Brackets

A high-precision sheet metal bracket is a precisely machined sheet metal part used to support, fix and connect other components or equipment. The following are the characteristics and applications of high-precision sheet metal brackets:

Features:

1. High precision: High-precision sheet metal brackets ensure the accuracy of their size and shape through precise processing technology to meet strict assembly requirements.

2. Stability: High-precision sheet metal brackets usually adopt strong structural design and rigid materials, which have stable performance and can withstand certain loads and vibrations.

3. Lightweight: The sheet metal processing technology makes the high-precision sheet metal bracket have a lighter weight, which is suitable for applications where the overall weight needs to be reduced.

4. Multifunctional: High-precision sheet metal brackets can be designed according to specific needs, providing various additional functions, such as ventilation holes, heat sinks, cable threading slots, etc.

Application:

1. Electronic equipment: high-precision sheet metal brackets are often used to support and fix electronic equipment, such as server brackets, circuit board brackets, chassis brackets, etc.

2. Communication equipment: In the field of communication, high-precision sheet metal brackets are used to support and fix antennas, communication equipment and cabinets, etc.

3. Medical equipment: High-precision sheet metal brackets are suitable for various fixing and supporting requirements in medical equipment, such as medical instrument brackets, testing equipment brackets, etc.

4. Optical equipment: In the optical field, high-precision sheet metal brackets are used to support and fix optical devices, laser equipment, etc., to ensure their precise position and stability.

5. Industrial equipment: high-precision sheet metal brackets are widely used in the support and fixing of various industrial equipment, such as mechanical equipment brackets, automation equipment brackets, etc.

The high-precision sheet metal bracket plays an important supporting and fixing role in various fields, and its precise processing and stable performance ensure the normal operation and reliability of the equipment.

In Which Fields Can Sheet Metal Brackets Be Applied?

A sheet metal bracket is a common sheet metal part used to support, fix and install other components or equipment. It can be applied in many fields, including but not limited to the following aspects:

1. Electronic and communication equipment: sheet metal brackets are often used in electronic and communication equipment, such as servers, routers, switches, communication base stations, etc. They are used to secure and support equipment and provide necessary spatial and structural support.

2. Medical equipment: In the medical industry, sheet metal brackets are widely used in various medical equipment, such as medical instruments, surgical instruments, testing equipment, etc. Brackets are used to secure and support components of equipment and ensure their correct position and stability.

3. Optical and laser equipment: Sheet metal brackets play an important role in the optical and laser fields. They are used to support and hold optics, lasers, optical systems, etc. to ensure their precise position and stability.

4. Industrial and manufacturing equipment: In the industrial and manufacturing fields, sheet metal brackets are often used in various mechanical equipment and automation equipment. They provide support and fixation to ensure the stability and reliability of the equipment during operation.

5. Automobiles and vehicles: Sheet metal brackets are also used in the manufacture and maintenance of automobiles and vehicles. They are used to support and hold body parts, chassis components and electronics, among other things.

6. Furniture and display racks: In furniture manufacturing and commercial display, sheet metal brackets are widely used for structural support of various furniture and display racks. They provide stability and reliability, supporting the placement of furniture and display items.

In addition to the fields mentioned above, sheet metal brackets can find applications in aerospace, energy, construction, and other industries. Its flexibility and customizability make sheet metal brackets an important component in a variety of industries for supporting and securing a variety of equipment and structures.

EN

EN  English

English Español

Español Deutsch

Deutsch

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)